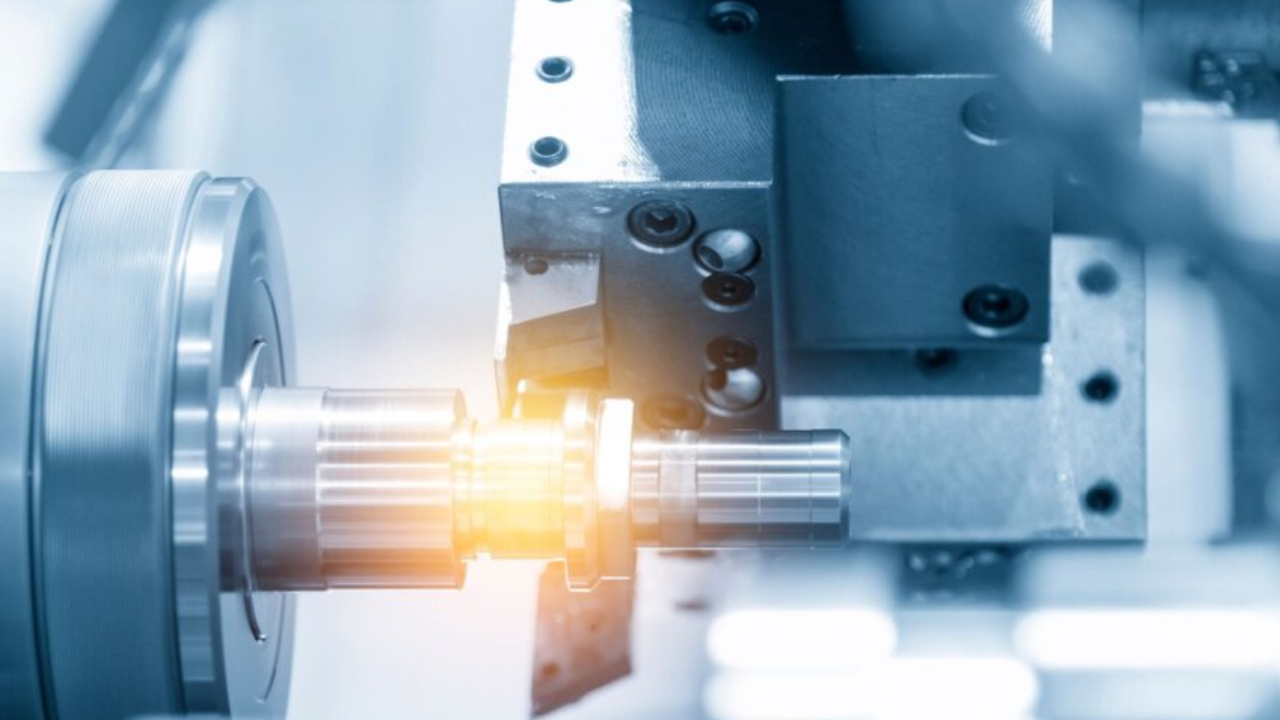

CNC machining stands as a cornerstone of current manufacturing, revolutionizing how industries create precision components and products. In contrast to traditional manual techniques, CNC machining utilizes automated controls to automate and precisely execute complex machining obligations. This technology translates virtual designs into physical objects with unrivaled accuracy, consistency, and performance.

The significance of CNC machining spans a multitude of industries. Its capability to supply intricate components with tight tolerances guarantees reliability and performance in important applications. As industries evolve and call for better requirements of quality and customization, cnc machining continues to play a pivotal role in driving innovation and shaping the future of international production.

Applications Of CNC Machining In Different Sectors

Computer numerical control (CNC) machining has revolutionized manufacturing throughout numerous industries by way of enhancing precision, performance, and versatility in production processes. This technology makes use of automated controls to operate and control system tools, considerably enhancing the consistency and accuracy of manufactured parts compared to traditional manual methods. The applications of CNC machining are numerous and span numerous sectors, each taking advantage of its capabilities in particular approaches.

Automotive Industry

Within the automobile industry, CNC machining plays an important role in producing additives with excessive precision and reliability. Engine elements, transmission components, brake structures, and chassis elements are commonly produced using CNC machining methods. The capacity to create complex geometries and ensure tight tolerances makes CNC machining essential for maintaining safety requirements and optimizing vehicles' overall performance.

Medical Industry

In the medical industry, CNC machining contributes significantly to producing particular and sterile components utilized in diagnostic devices, surgical devices, implants, and prosthetics. The biocompatibility and dimensional accuracy plausible with CNC machining makes sure that medical gadgets meet regulatory requirements and are carried out reliably within the human body. Superior substances such as clinical-grade chrome steel, titanium alloys, and bioresorbable polymers are machined to exact specifications, helping medical advancements and patient care.

Electronics and Consumer Goods

The electronics enterprise benefits from CNC machining for growing custom properties, connectors, warmth sinks, and different additives essential for digital devices. CNC technology enables producers to prototype and mass-produce complicated designs hastily, helping innovation and product improvement cycles. Customer items leverage CNC machining for precision manufacturing of casings, buttons, and inner components, ensuring functionality, sturdiness, and aesthetic appeal.

Industrial Equipment and Tooling

CNC machining performs an essential role in producing business equipment, device components, and specialized tooling utilized in diverse production strategies. From large-scale production equipment to precision devices and die sets, CNC technology enables the introduction of durable and green gear that enhances productivity and holds extraordinary standards across industries, including metalworking, plastic molding, and woodworking.

Architecture and Construction

In architecture and construction, CNC machining is applied for fabricating custom architectural components, elaborate facades, molds, and structural elements. CNC routers and mills can carve certain styles into stone, wood, metal, and composite materials, permitting architects to understand complex designs with precision and consistency. This technology additionally helps sustainable building practices by optimizing material utilization and decreasing waste in production tasks.

Artwork And Design

Beyond industrial applications, CNC machining has observed a niche in artwork, sculpture, and layout. Artists and designers use CNC technology to create difficult sculptures, furniture portions, jewelry, and ornamental objects that mix inventive, imaginative, and prescient with precision production strategies. CNC routers and 3D printers permit for the exploration of the latest forms and materials, pushing the boundaries of creativity and craftsmanship in modern artwork and design.

Sum Up

CNC machining is a versatile and imperative technology that continues to power innovation and performance across various industries. As technology advances and manufacturing techniques evolve, CNC machining stays at the forefront, allowing industries to fulfill growing needs for quality, reliability, and sustainability in a competitive international market. Embracing the CNC era not only most effectively complements operational efficiencies but also fosters creativity and enables breakthroughs in product development and design across various sectors internationally.